Sight Glass Manufacturer

Sight Glass

The sight glass is one of the main accessories of industrial equipment. The sight glass on the market today is mainly divided into pipe sight glass and pressure vessel sight glass.

REQUEST A QUOTE FOR MORE DETAILS

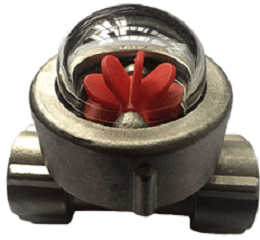

Pipeline Sight Glass

The pipeline sight glass is one of the main accessories of the industrial pipeline device. It can observe the flow reaction of liquid, gas, steam and other media in the pipeline at any time, monitor the production, and avoid accidents in the production process. Pipelines are often used in petroleum, chemical, chemical fiber, pharmaceutical and other production pipelines.

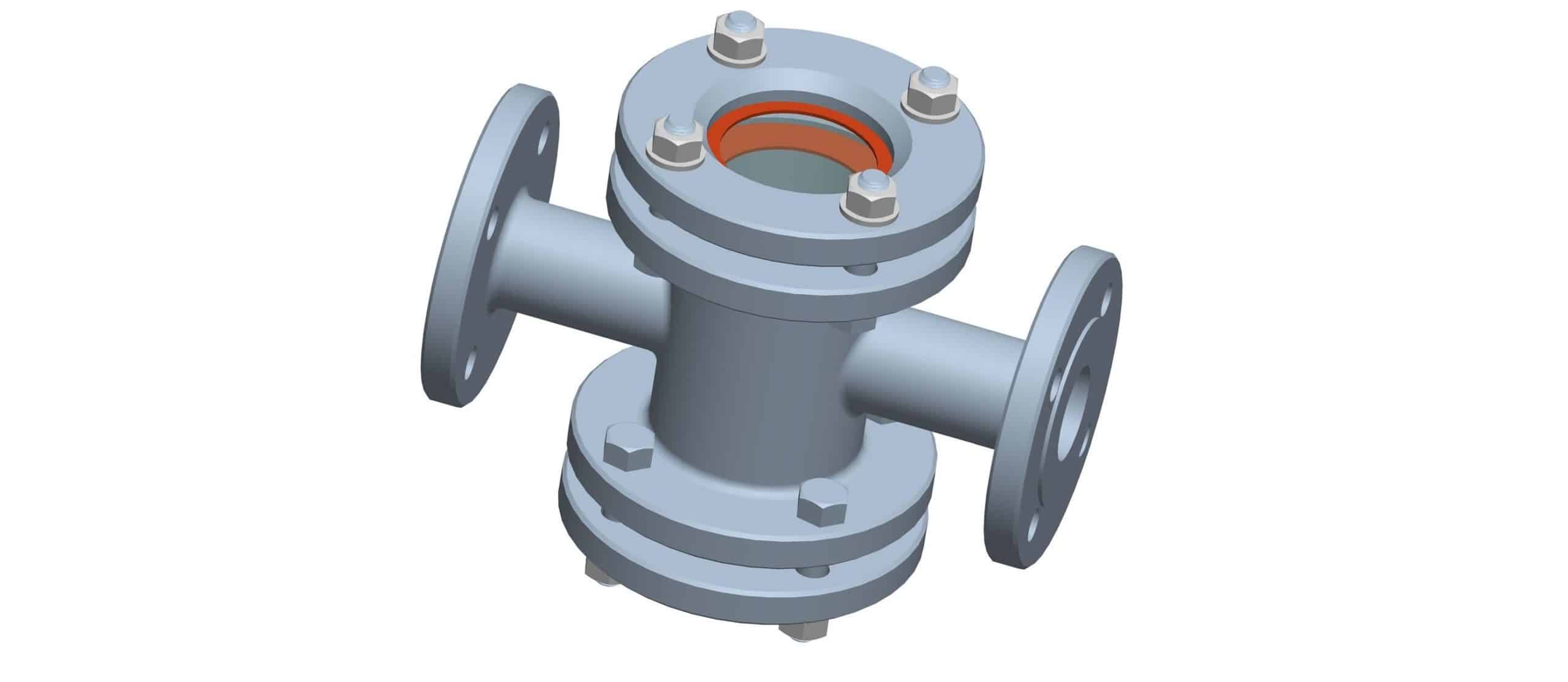

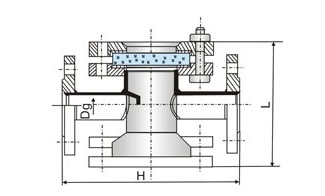

Pressure Vessel Sight Glass

Pressure vessel sight glass, also known as equipment sight glass, is a product used to observe the change of medium in chemical, petroleum, cosmetics, medicine and other industrial equipment containers. The operator can adjust or control the filling amount according to the display, so as to ensure that the medium in the container is always in the normal range. Liquefied gas tanks, tankers, gas-liquid reactors, reactors and other containers need to be equipped with mirrors to prevent accidents caused by over loading or unbalanced material reaction caused by over feeding.

Advantages of Sight Glass

The pipeline sight glass has the advantages of small installation size, small driving torque, simple and rapid operation, good flow regulation function and sealing characteristics. It is the leading sight glass form in the application field of large and medium caliber, medium and low pressure.

In the process of urea production, in the medium and low pressure tower with sight glass, because of the characteristics of high operating temperature and strong liquid corrosion, the sight glass of the liquid level meter is damaged and the bottom plate of the sight glass is deformed. In the process of installing the sight glass, sometimes the sight glass is easy to crack due to uneven stress. If it is not found in time, leakage will occur after driving. At this time, it is necessary to park the whole system for hot washing. This not only brings difficulties to the long-term safe operation of the system, but also seriously affects the power of urea production.

The pressure vessel sight glass produced by our company is mainly manufactured according to the latest standard, and the size and performance are manufactured and inspected in strict accordance with the standard requirements.

Sight Glass Parts Material

Body

Carbon Steel, Stainless Steel

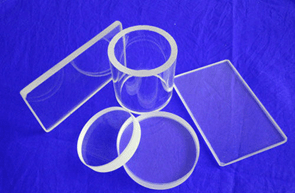

Glass

Organic glass, toughened glass, borosilicate glass, toughened borosilicate glass, quartz glass, aluminosilicate glass, etc

Seal

Fluororubber, PTFE, graphite+SS

Where Does Sight Glass Used

The pipe sight glass can be used in the chemical tower with high temperature, strong corrosion, easy poisoning, high risk and easy crystallization, so as to ensure its safe production. The pressure vessel sight glass should be selected correctly according to the medium, high working pressure and temperature of the pressure vessel.

The pressure vessel for liquefied gas containing inflammable, extremely toxic and highly hazardous medium shall adopt high-temperature and high-pressure small-diameter vessel sight glass, and shall be equipped with protection device to prevent leakage.

For containers used outdoors in cold areas, or due to the large difference between the medium temperature and the ambient temperature, the glass material with higher abrupt change temperature should be selected.

If the light is insufficient, the container sight glass with light device should be selected, and the explosion-proof level should be selected according to the site conditions.

The low-pressure vessel can use the low-pressure sight glass, and the diameter can be larger.

Sight Glass Selction Guide

Glass material of industrial sight glass is mainly divided into high temperature resistant glass, high pressure resistant glass and high temperature and high pressure resistant glass. Each type of glass has its own unique performance. See the introduction of material and performance for specific capability.

#1 High temperature resistant sight glass material

The glass has excellent temperature resistance, can be used under various high temperature conditions, does not crack, and has excellent heat resistance stability. It is a special glass for various high temperature windows or views.

Characteristic:

Temperature resistance: 350 ℃ ~ 1200 ℃;

Thermal shock temperature: 180 ℃ ~ 1100 ℃;

Bending strength: 80 ~ 220MPa;

#2 High-pressure resistant sight glass material

The outstanding features of the glass are high compressive strength and bending strength, and stable mechanical performance. It is a special product for various high pressure vessel mirrors or windows.

Characteristic:

High compressive strength: it can meet the working condition of 1 ~ 10.0MPa;

Bending strength: 100 ~ 220MPa;

#6 High temperature and high pressure resistant glass

The product not only can bear certain pressure, but also has good cold and heat resistance, and does not crack in the hot and cold environment.

characteristic:

High temperature resistance: up to 1200 ℃.

The coefficient of thermal expansion is very small, equivalent to 1 / 12-1 / 20 of ordinary glass

How to choose the right glass for sight glass

1. Round glass sheet: cross sight glass, equipment sight glass, sight glass with light

2. Glass tube: glass tube sight glass

3. Glass strip: suitable for strip sight glass

4. Hemispherical glass: hemispherical sight glass

Sight Glass Appearance Inspection

1. The color is colorless and transparent, with light green or light yellow allowed;

2. There are no dispersed grooves, alkaline bubbles and break bubbles;

3. No filaments or stripes

4. No refractory sand, iron filings or other impurities, transparent crystal and raw material white spots less than 2 in 1cm2 area, not on the surface or cracking;

5. There are no more than two slight abrasions with length less than 30mm outside the perimeter of 15mm;

6. There are no pits and wrinkles on the two sealing surfaces, no pits with depth greater than 2 mm on the side within 3 mm of chamfering oblique line, and five wrinkles with depth greater than 2 mm on the whole side;